What is anodising ?

The process involves placing aluminum in an electrolyte, concentrated sulfuric acid, and passing a low voltage current through the part.

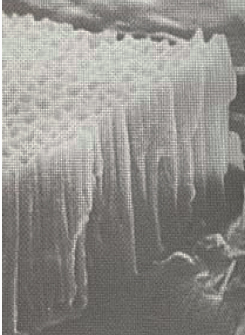

The aluminum part is connected to the positive (anode) side and the negative side is connected to a cathode made of lead. This causes the aluminum to oxidize, similar to steel rusting, with the net result of a very hard, tough abrasion resistant protective coating being formed. An interesting 'quirk' of this process is that the film formed looks like honeycomb, and has 'tubes' growing up from the aluminum. These tubes conveniently allow color dyes to flow into them

For the technically inclined, the surface of the aluminum actually grows a layer of aluminum oxide on itself, which is then transformed into aluminum hydroxide (anodize) and finally

hydroxide monohydrate. The whole anodize layer is non conductive.

The process involves placing aluminum in an electrolyte, concentrated sulfuric acid, and passing a low voltage current through the part.

The aluminum part is connected to the positive (anode) side and the negative side is connected to a cathode made of lead. This causes the aluminum to oxidize, similar to steel rusting, with the net result of a very hard, tough abrasion resistant protective coating being formed. An interesting 'quirk' of this process is that the film formed looks like honeycomb, and has 'tubes' growing up from the aluminum. These tubes conveniently allow color dyes to flow into them

For the technically inclined, the surface of the aluminum actually grows a layer of aluminum oxide on itself, which is then transformed into aluminum hydroxide (anodize) and finally

hydroxide monohydrate. The whole anodize layer is non conductive.